No pollution medical blister aluminum plastic recycling plant

ALUMINUM PLASTIC CRUSHING SEPARATING PLANT

The function is to separate and recover the waste aluminum and

plastic from the scrap aluminum plastic composites.

Our No pollution medical blister aluminum plastic recycling plant

can be used for recycling all kinds of aluminum and plastic

composite such as medical blister, aluminum plastic plate, aluminum

plastic foil, and aluminum plastic package bags etc.

GET THE LATEST QUOTE ↓

PROCESS DESCRIPTION

The aluminum and plastic materials firstly crushed by the knife

crusher into 10mm pieces, and then grinding by the water cooling

turbo type grinding machine into aluminum and plastic fine powders.

Then separated by the rotary screen, the big size will back into

the grinding machine and the fine powders will into the

electrostatic separator, finally the aluminum and plastic would be

separated.

CUSTOMIZE YOUR SOLUTIONS ↓

CHOOSE THE MODEL YOU NEED

TECHNICAL PARAMETERS

| Model | Capacity (Kg/H) | Power (Kw) | Weight (T) |

| ZYWAP-300 | 300 | 62 | 7.5 |

| ZYWAP-500 | 500 | 98 | 12.5 |

| ZYWAP-1000 | 1000 | 170 | 19.5 |

NOTE:1. The Price depends on your capacity and configuration of the

machinery;

2. Working voltage:380±10V(415V ,440V also can be custom)

TELL US THE MODEL YOU NEED ↓

RAW MATERIALS AND FINAL PRODUCTS

The following picture is the result of testing the No pollution

medical blister aluminum plastic recycling plant by some customers.

We will save and send samples of sorted aluminum powder and plastic

powder for our customers, You can send your materials to us and we

will test the machine for you without charging any fees.

Aluminum powder and plastic powder from medical plates

Welcome to our factory and test the machine with the materials you

specified

TELL US YOUR RAW MATERIAL ↓

COMPARE WITH OTHER SUPPLIERS

India customer visited our factory for No pollution medical blister

aluminum plastic recycling plant. He visited several suppliers

during his tour in China and compared the aluminum powder separated

from our system with those of other suppliers. He is quite

satisfied with our equipment.

Note: The more uniform of material particles after milling, the

better the sorting result.

CUSTOMIZE YOUR SOLUTIONS ↓

MACHINE FEATURES

REQUEST A QUOTE RIGHT NOW ↓

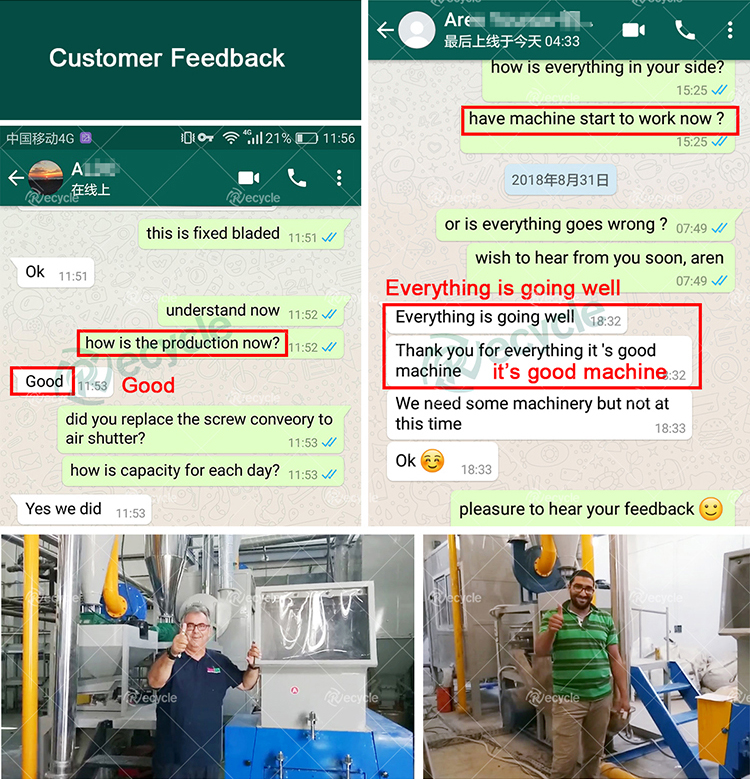

CUSTOMER FEEDBACK

CUSTOMER SITE

CUSTOMIZE YOUR SOLUTIONS ↓

WHY CHOOSE RECYCLERECYCLE support team has more than 20 professional engineers to

provide clients professional solutions, facing multitudinous

requirements, RECYCLE team always pay patience and offer as more

options as possible, to ensure every users have all security while

running our machines, in this way, RECYCLE keep growing and now

owns ability of taking large wood to sawdust/powder plant, scrap

tires to rubber granules/powder plant, waste metal downsize

project,WEEE recycle plant in China or abroad, under the support of

internal business department, RECYCLE is able to take"Turn-Key"

projects in China or abroad.

WELCOME TO VISIT OUR FACTORY-- Our customers from over 30 countries and regions.

-- High efficiency,high quality,lowcost. No chemical process

involved and no pollution.

-- We provide engineer to help you with installation, training, our

engineers are also available to install overseas if you need.

FRIENDLY COOPERATION

CONTACT US ↓